Phthalates Testing and Analysis

Your Industry, Our Focus

A Hidden Hazard in Flexible Plastics

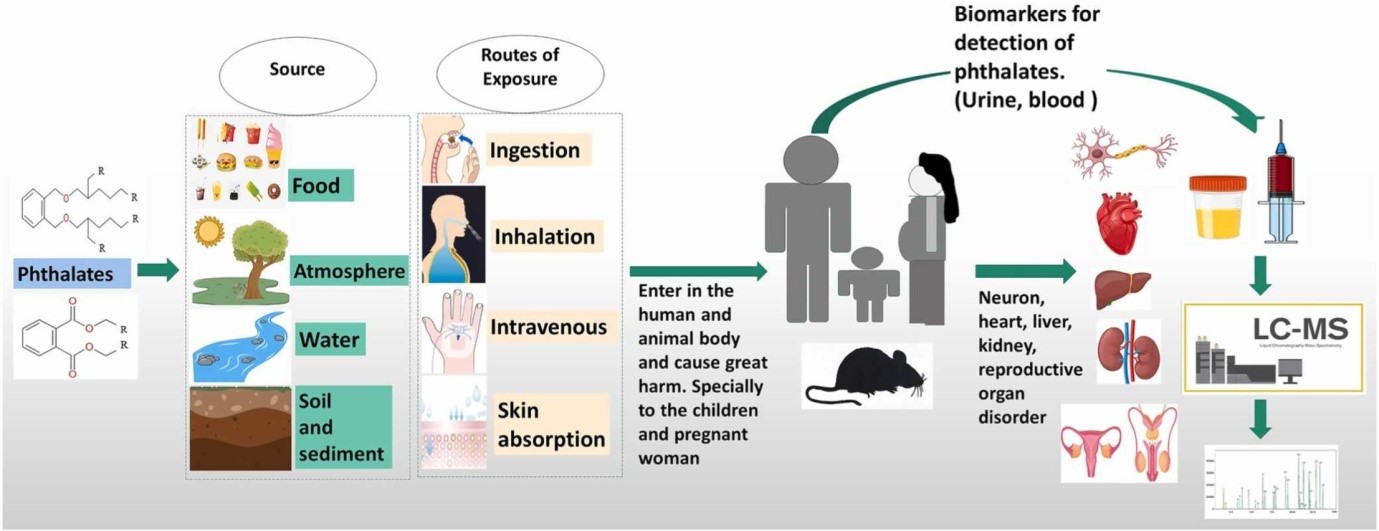

Phthalates are industrial chemicals that serve as plasticisers additives used to enhance the flexibility, transparency, and longevity of plastics like PVC. However, their widespread use comes at a cost: phthalates are not permanently bonded to the plastic matrix, meaning they can leach into the environment and, most concerningly, into our food. From plastic wrap to tubing and conveyor belts, phthalates have infiltrated nearly every step of modern food processing and packaging. And because they act as endocrine disruptors, even small amounts may have outsized effects on health.

Phthalates Detected in Food and Packaging

|

Phthalate |

Full Chemical Name |

|

DEHP |

Di(2-ethylhexyl) phthalate |

|

DBP |

Dibutyl phthalate |

|

DINP |

Diisononyl phthalate |

|

DIDP |

Diisodecyl phthalate |

|

BBP |

Butyl benzyl phthalate |

These phthalates are commonly found in food products due to their migration from packaging and processing equipment. Their detection in food has led to increased regulatory scrutiny across the globe.

Common Sources of Phthalate Contamination in the Food Chain

|

Phthalate |

Common Sources in the Food Chain |

|

DEHP |

PVC-based packaging, plastic wrap, tubing, sealing gaskets |

|

DBP |

Printing inks, adhesives, plastic film coatings |

|

DINP |

Flexible PVC used in tubing, gloves, conveyor belts |

|

DIDP |

Plastic containers, food contact laminates, processing hoses |

|

BBP |

Adhesives, conveyor belt coatings, flooring in food production areas |

How Phthalates Enter the Food Chain

|

Contamination Pathway |

Where It Happens |

Risk Factor |

Food Types Affected |

|

1. Migration from Packaging |

Flexible plastic films, PVC containers, sealing lids and gaskets |

Heat, fat content, and storage duration increase migration rate |

Cheese, edible oils, deli meats, ready-to-eat meals |

|

2. Transfer via Equipment |

Conveyor belts, tubing, hoses, gloves, plastic-coated food contact surfaces |

Mechanical pressure and direct food contact cause leaching |

Dairy products, bakery items, snacks, beverages |

|

3. Contaminated Materials |

Printing inks, imported packaging, adhesives, coated wrappers |

Poor traceability introduces unregulated or hidden phthalates |

Instant noodles, dry snacks, packaged and printed items |

Importance of Phthalate Testing in the Food Industry

|

Purpose |

Description |

|

Food Safety |

Detects migration of toxic plasticisers from packaging into food |

|

Regulatory Compliance |

Ensures food contact materials meet global migration limits |

|

Brand Protection |

Prevents consumer backlash, recalls, and legal actions |

|

Quality Assurance |

Verifies safe materials in processing and packaging supply chains |

|

Export Readiness |

Supports compliance with EU, US, and Codex import regulations |

Health and Environmental Impacts of Phthalates

|

Category |

Implication |

Description |

|

Health Risks |

Endocrine Disruption |

Mimic or block natural hormones, interfering with reproductive, thyroid, and metabolic functions. |

|

Reproductive Toxicity |

Linked to low sperm count, hormonal imbalance, early puberty, and fertility issues. |

|

|

Child Development Effects |

Associated with neurodevelopmental disorders like ADHD, lower IQ, and speech delays. |

|

|

Metabolic Disorders |

Increases risk of obesity, insulin resistance, and type 2 diabetes. |

|

|

Immune & Respiratory Issues |

May contribute to asthma, allergies, and weakened immune responses. |

|

|

Environmental |

Water & Soil Contamination |

Leach into groundwater and soil from landfills and plastic waste, polluting ecosystems. |

|

Harm to Aquatic Life |

Disrupt reproductive and growth patterns in fish and other aquatic organisms. |

|

|

Bioaccumulation |

Accumulate in the food chain, posing long-term ecological and human exposure risks. |

|

|

Indoor Air Pollution |

Released from PVC flooring, toys, and packaging, contaminating household dust and indoor air. |

|

|

Persistence in Environment |

Resistant to breakdown under anaerobic conditions; remains in the environment for extended periods. |

Why Phthalate Testing Is Essential

Phthalates are invisible, odorless, and often present in trace amounts yet their potential for harm is significant. Testing is not just a regulatory requirement, but a critical measure for ensuring food safety, protecting public health, and securing consumer trust.

Reasons for Phthalate Testing

- Food Safety Assurance

Testing helps detect migration of harmful plasticisers into food products, especially in high-risk categories like fatty foods and heat-processed items. - Regulatory Compliance

Authorities such as FSSAI, FDA, and the EU require strict limits on phthalate levels in food contact materials (FCMs) and food products. Failure to comply can result in bans, recalls, or export restrictions. - Brand and Consumer Protection

Proactive testing prevents reputational damage, protects consumers from long-term health risks, and reduces the risk of product recalls or legal action. - Supply Chain Transparency

Ensures raw materials, inks, adhesives, and packaging components meet safety standards and are free from unauthorized plasticisers.

What We Test - and Why

|

What to Test |

Why It’s Tested |

|

Finished Food Products |

Detect phthalate residues that may have migrated from packaging or during processing |

|

Food Contact Materials (FCMs) |

Verify compliance with global migration limits (e.g., EU 10/2011, US FDA) |

|

Packaging Films and Containers |

Assess risk of migration under typical storage or thermal conditions |

|

Flexible Tubing, Gloves, Conveyor Belts |

Identify contamination sources during food manufacturing and handling |

|

Printing Inks and Adhesives |

Detect hidden phthalates from coated wrappers, labels, and bonded packaging layers |

|

Raw Materials (plastics, masterbatches) |

Ensure materials are free from non-compliant or banned phthalates before being used in production |

|

Environmental Samples (dust, water, soil) |

Evaluate workplace and environmental exposure risks during manufacturing or disposal |

Global Standards and Regulations on Phthalates

|

Region |

Regulatory Body |

Key Regulation/Update |

Limit/Restriction |

|

India |

FSSAI |

Food Safety and Standards (Packaging) Amendment Regulations, 2021 |

DEHP migration limit: ≤ 1.5 mg/kg in food contact plastics |

|

USA |

FDA |

As of May 2022, approval for 23 phthalates revoked; only 9 allowed in packaging |

Use restricted to a reduced list of permitted phthalates |

|

EPA |

National Primary Drinking Water Regulations |

DEHP in drinking water limited to 6 ppb |

|

|

European Union |

European Commission (EU) |

EU Regulation 10/2011 (amended in 2023) |

DEHP allowed only in repeated-use materials for non-fatty foods, limit: 0.6 mg/kg |

|

EFSA |

Tolerable Daily Intake (TDI) values set for consumer protection |

TDI values vary by phthalate type to limit long-term exposur |

https://www.fssai.gov.in/upload/advisories/2020/02/5e3d4cdfba1ebDirection_Antinomy_limits_Packaged_Drinking_Water_07_02_2020.pdf

https://eur-lex.europa.eu/eli/reg/2011/10/oj/eng

Eurofins Testing Services for Phthalates

Eurofins offers a comprehensive suite of analytical services tailored to detect, quantify, and evaluate regulated phthalates in food, food contact materials (FCMs), and environmental samples. Our state-of-the-art laboratories follow international standards and protocols to ensure compliance, traceability, and safety across the supply chain.

Scope of Testing Services

Eurofins tests for a broad range of regulated and priority phthalates, including:

- DEHP (Di(2-ethylhexyl) phthalate)

- DBP (Dibutyl phthalate)

- BBP (Butyl benzyl phthalate)

- DINP (Diisononyl phthalate)

- DIDP (Diisodecyl phthalate)

- DMP, DNOP, DPHP, and others as required by global regulations

Testing Matrices Covered

- Finished food products (especially fatty, processed, or packaged foods)

- Food contact materials (FCMs): films, containers, trays, lids, pouches

- Processing components: hoses, gloves, gaskets, conveyor belts

- Raw materials: masterbatches, inks, adhesives, laminates

- Environmental samples: air, dust, water (as part of workplace safety or EHS audits)

Testing Methods and Techniques Used

|

Method |

Purpose |

Typical Use Cases |

|

GC-MS (Gas Chromatography-Mass Spectrometry) |

High-sensitivity quantification of phthalates in food and FCMs |

Fatty foods, packaging films, oils, consumer goods |

|

LC-MS/MS (Liquid Chromatography-Tandem MS) |

Multi-residue detection in complex matrices |

Baby food, beverages, processed foods, emulsified samples |

|

Migration Simulation Testing |

Simulates migration of phthalates under food contact conditions |

Using food simulants (e.g., ethanol, acetic acid, oil) under varied time/temp |

|

FTIR/ATR-FTIR Spectroscopy |

Surface detection and polymer analysis |

Films, laminates, coatings, surface screening for phthalate residues |

|

SEM-EDX (Scanning Electron Microscopy with X-ray) |

Microstructural analysis for layered packaging and contaminant source ID |

Complex multilayer films, adhesives, barrier coatings |

Key Parameters Evaluated

- Specific Migration Limits (SMLs) based on EU Regulation (EU) 10/2011

- Maximum residue levels (MRLs) for phthalates in food (as per FDA/EFSA/Codex)

- Simulant-based migration levels under conditions of use (e.g., 40°C for 10 days)

- TDI (Tolerable Daily Intake) alignment through exposure modeling

- Cumulative phthalate levels to assess risk from multiple plasticisers in a product

Regulatory Compliance and Documentation Support

Eurofins supports clients in ensuring compliance with:

- EU Regulation (EU) 10/2011 and amendments (2023)

- US FDA regulations (post-2022 updates restricting 23 phthalates)

- FSSAI Packaging Regulations (India, 2021)

- Codex Alimentarius international food safety standards

We also assist in the preparation of:

- Declaration of Compliance (DoC) for FCMs

- Non-Intentionally Added Substances (NIAS) analysis

- Toxicological Risk Assessments in partnership with Eurofins toxicologists

- Audit documentation for GFSI, ISO 22000, BRC, and FDA/EFSA inspections

Additional Services

- Screening of inks, coatings, masterbatches, adhesives for phthalates and BPA

- Sensory evaluation to detect off-odors caused by plasticiser migration

- Packaging durability and leaching studies under real-world conditions

- Consulting and Training on packaging safety, raw material selection, and GMP compliance

- Supply chain audits and third-party verification services for packaging and processing vendors

Why Choose Eurofins for Phthalate Testing?

- Accredited Labs: ISO/IEC 17025, FDA-recognized (LAAF Program), NABL certified

- Global Reach, Local Expertise: Labs in India, EU, USA, Middle East & Asia-Pacific

- End-to-End Solutions: From product screening to market-ready certification

- Proven Track Record: Trusted by top FMCG brands, exporters, and government agencies