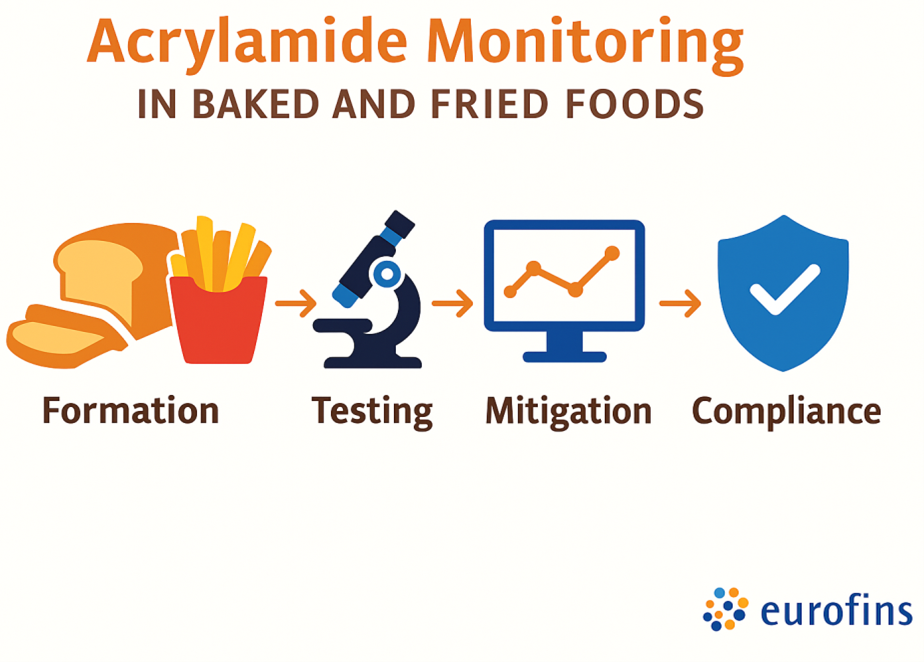

Acrylamide Monitoring in Baked and Fried Foods

Introduction

Acrylamide is an undesirable heat-induced contaminant that forms in carbohydrate-rich foods during baking, frying, roasting, or toasting at temperatures exceeding 120°C. It is produced primarily through the Maillard reaction a chemical reaction between reducing sugars (glucose, fructose) and the amino acid asparagine that also contributes to browning and flavor.

Since its discovery in foods in 2002, acrylamide has been a major focus for food safety authorities worldwide due to its classification as a probable human carcinogen (Group 2A) by the International Agency for Research on Cancer (IARC). Chronic exposure may increase risks of neurological, reproductive, and genotoxic effects.

At Eurofins Food Testing Laboratories, we provide comprehensive acrylamide monitoring and control services combining state-of-the-art analytical technologies, scientific expertise, and regulatory guidance to help manufacturers meet compliance and reduce consumer risk.

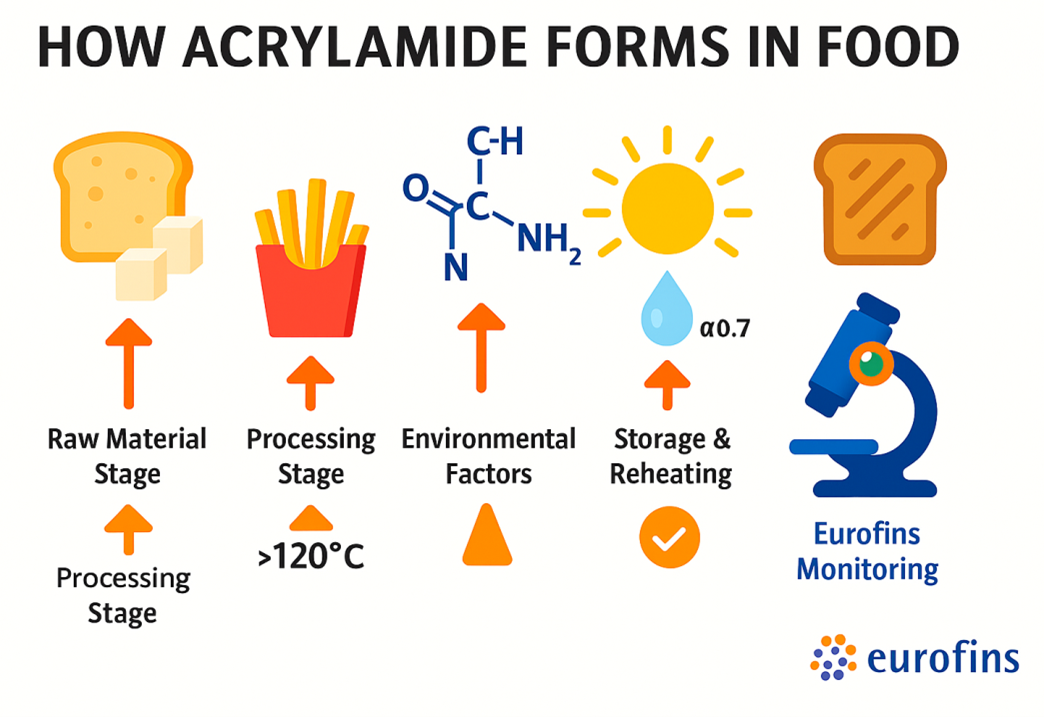

How Acrylamide Forms in Foods

Acrylamide formation depends on a complex interplay of precursor concentration, temperature, moisture, and cooking time.

|

Stage |

Key Process |

Example |

Control Strategy |

|

Raw Material Stage |

High asparagine and sugar content |

Wheat flour, potatoes, coffee beans |

Ingredient screening, variety selection |

|

Processing Stage |

High heat induces Maillard reaction |

Baking, frying, roasting |

Temperature and time optimization |

|

Storage and Reheating |

Continued or secondary formation during reheating |

Toasted bread, re-fried snacks |

Packaging control, consumer handling advice |

Typical Food Categories and Risk Levels

|

Food Category |

Common Products |

Acrylamide Formation Mechanism |

Risk Level |

|

Bakery Products |

Bread crusts, biscuits, cookies |

Sugar–asparagine reaction during baking |

Moderate to high |

|

Potato Products |

Chips, fries |

Reducing sugars react with amino acids |

Very high |

|

Cereal Products |

Breakfast cereals, granola |

Roasting and extrusion |

Moderate |

|

Coffee and Cocoa |

Roasted coffee, cocoa powder |

Roasting of beans |

Moderate |

|

Snacks & Infant Foods |

Crackers, teething biscuits |

Overheating during drying |

Low to moderate |

Health Implications

- Carcinogenicity: Acrylamide and its metabolite glycidamide bind to DNA, potentially causing mutations.

- Neurotoxicity: Chronic exposure affects the nervous system, leading to coordination issues.

- Reproductive toxicity: Animal studies indicate hormonal and fertility impacts at high doses.

- Regulatory concern: Recognized as a genotoxic carcinogen no safe threshold is established.

Regulatory Framework

FSSAI Stance on Acrylamide

Acrylamide is not explicitly listed with a specific permissible limit in the FSSAI 2023 Compendium of Contaminants, Toxins, and Residues. Instead, it is managed through process hygiene and preventive manufacturing controls for foods prone to acrylamide formation, such as biscuits, bread, snacks, potato products, and coffee.

Under Section 16(5) (March 2024) on “Approved Processing Aids,” FSSAI mandates enzymatic treatments, specifically glucose oxidase and asparaginase, to reduce acrylamide in cereal- and potato-based foods during baking and frying. These enzymes, listed in Appendix C (Tables 11 and 11A), are permitted under Good Manufacturing Practice (GMP) residue levels, ensuring no toxic remnants in the final product.

EU Regulation on Acrylamide in Baked and Fried Foods

The European Union regulates acrylamide under Commission Regulation (EU) No. 2017/2158, effective since April 11, 2018. This regulation mandates food business operators (FBOs) to implement mitigation measures and adhere to benchmark levels to control acrylamide in foods such as French fries, potato crisps, bread, breakfast cereals, biscuits, coffee, and baby food. The goal is to keep acrylamide levels as low as reasonably achievable (ALARA) through preventive measures and testing protocols.

EU Benchmark Levels for Acrylamide (Annex IV)

|

Food Category |

Benchmark Level (µg/kg) |

|

French fries (ready-to-eat) |

500 |

|

Potato crisps, other potato snacks |

750 |

|

Soft bread |

50 (wheat) / 100 (other) |

|

Biscuits and wafers |

350 |

|

Crackers, crispbread |

400 / 350 |

|

Gingerbread |

800 |

|

Breakfast cereals |

150–300 (depending on cereal type) |

|

Roast coffee |

400 |

|

Instant coffee |

850 |

|

Baby food (non-biscuits) |

40 |

|

Baby biscuits and rusks |

150 |

|

Coffee substitutes (chicory-based) |

Up to 4,000 |

https://www.legislation.gov.uk/eur/2017/2158/pdfs/eur_20172158_adopted_en.pdf

Factors Influencing Acrylamide Formation

|

Factor |

Description |

Impact |

|

Raw Material Composition |

High levels of asparagine and reducing sugars |

Increased precursor load |

|

Processing Temperature & Time |

Extended heating > 120°C |

Rapid acrylamide generation |

|

Moisture Content |

Low water activity (aᵥ < 0.7) promotes Maillard reaction |

Higher acrylamide yield |

|

pH Level |

Alkaline pH accelerates reaction |

Increased risk |

|

Storage Conditions |

Oxidation or reheating events |

Secondary formation |

|

Formulation Ingredients |

Use of baking soda, caramel coloring |

Alters precursor balance |

Eurofins Analytical Testing Capabilities

Eurofins laboratories employ validated, trace-level detection methods for accurate quantification of acrylamide in foods, intermediates, and ingredients.

Analytical Platforms

- Liquid Chromatography–Tandem Mass Spectrometry (LC-MS/MS): Quantitative, sensitive detection at ppb (µg/kg) level.

- Gas Chromatography–Mass Spectrometry (GC-MS/MS): High-throughput screening for volatile compounds.

- Isotope Dilution Techniques: Stable isotope-labeled standards ensure accuracy and recovery validation.

- Thermal Desorption GC: For volatile acrylamide-related byproducts.

Contaminant Analysis

Acrylamide often co-occurs with other process contaminants; Eurofins provides multi-contaminant screening for:

- 5-Hydroxymethylfurfural (5-HMF)

- Furans and methylfurans

- 3-MCPD and glycidyl esters (GE)

- Polycyclic Aromatic Hydrocarbons (PAHs)

This integrated approach helps manufacturers manage multiple risk categories simultaneously.

Data Reporting and Digital Traceability

Eurofins supports full transparency through digital tools:

|

Tool |

Function |

|

Smart LIMS |

Real-time lab data management and CoA generation |

|

Smart View |

Client dashboard with graphical trend visualization |

|

Blockchain Integration |

Traceable certificate sharing with buyers and regulators |

Case Study: Acrylamide Reduction in Biscuits

Challenge: A major biscuit exporter to the EU faced repeated non-compliance due to acrylamide exceedance.

Eurofins conducted raw material precursor screening using LC-MS/MS to trace sources linked to elevated asparagine and sugar levels. Through targeted process optimization—adjusting baking temperature, pH, and formulation, along with the use of asparaginase enzyme—acrylamide levels were reduced from high to within safe international limits. The biscuits maintained their signature taste, color, and texture, restoring compliance and ensuring consistent export acceptance.

Why Partner with Eurofins

- Global network of ISO/IEC 17025-accredited laboratories

- Detection at ultra-trace levels (ppt–ppb)

- End-to-end workflow: ingredient to process to finished product

- Rapid reporting (48–72 hrs) via digital platforms

- Experience across bakery, snack, coffee, and infant food sectors

Protect your brand, consumers, and export credentials by proactively controlling acrylamide risks.

Eurofins Food Testing Services offer an integrated framework — from advanced LC-MS/MS quantification to customized process improvement and compliance certification.

Partner with Eurofins today to

- Detect and minimize acrylamide formation

- Comply with global regulations (EU 2017/2158, FSSAI, Codex)

- Build safer, transparent, and export-ready products

Enquire now: www.eurofins.in/food-testing/enquire-now/